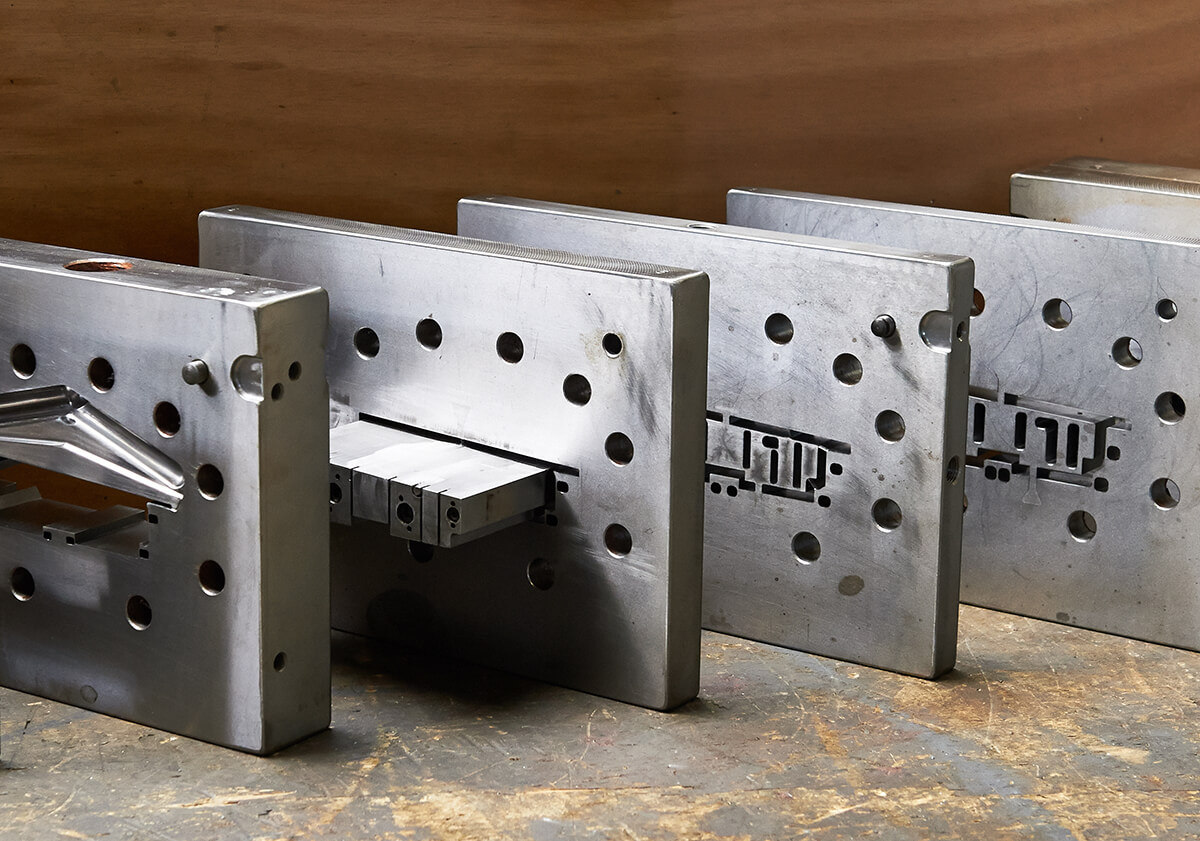

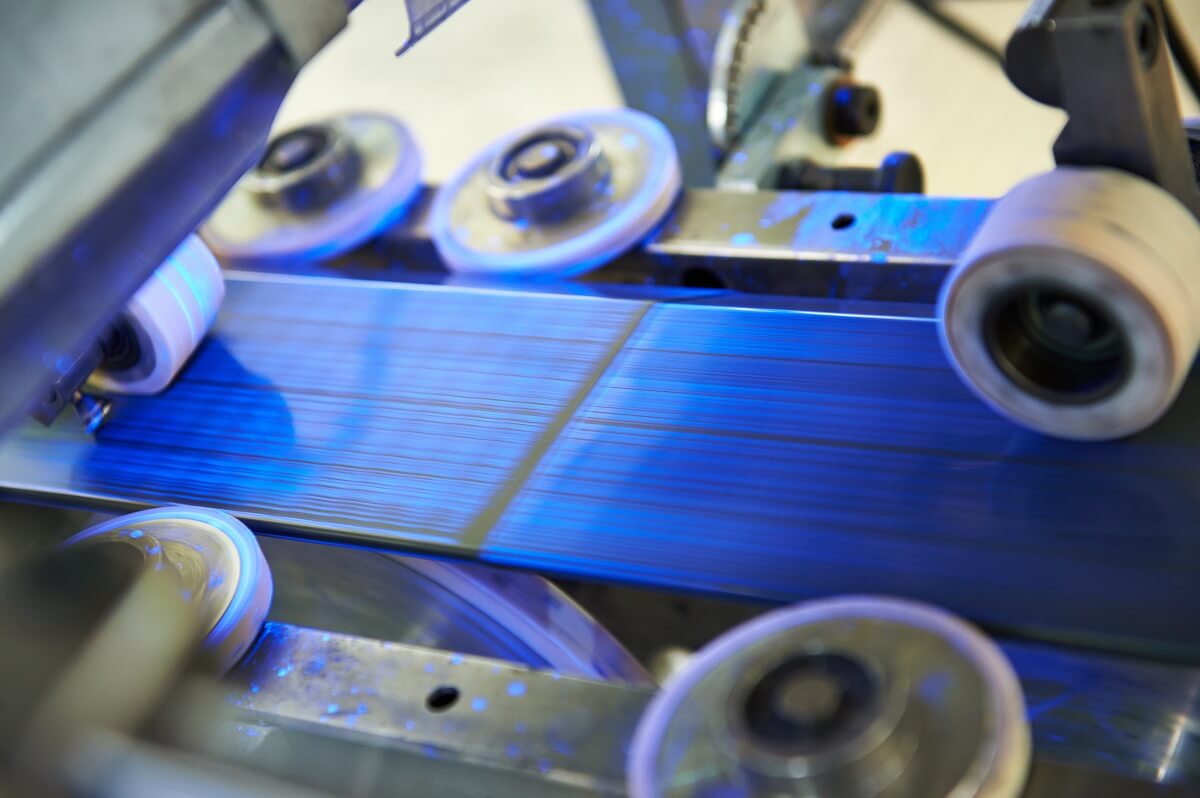

At Geplast, we can help you realise your specific technical profile projects. We have many key strengths that enable us to meet all our customers’ requirements: research & development, design, tooling and process manufacturing. We attach particular importance to building a long-term relationship with each of our customers, including complete confidentiality of the project we are working on.

Today, Geplast Engineering works in sectors as varied as general industry, construction, exterior fittings, the naval sector, agriculture, light housing, point-of-sale advertising, and so on. Since its creation in 2003, hundreds of specific profiles have been produced.

Meeting the most stringent requirements

From defining specifications to delivering the finished product, we’re with you every step of the way. Our dedicated teams can advise you on the choice of technologies, processes and materials best suited to your needs.

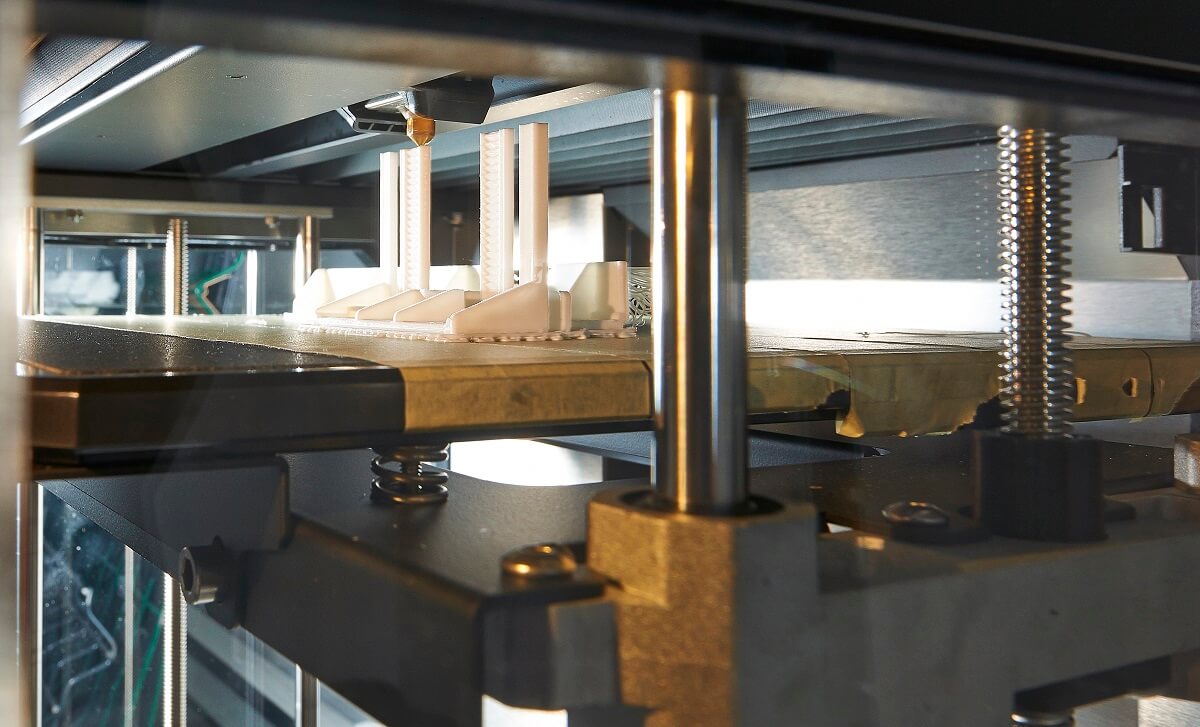

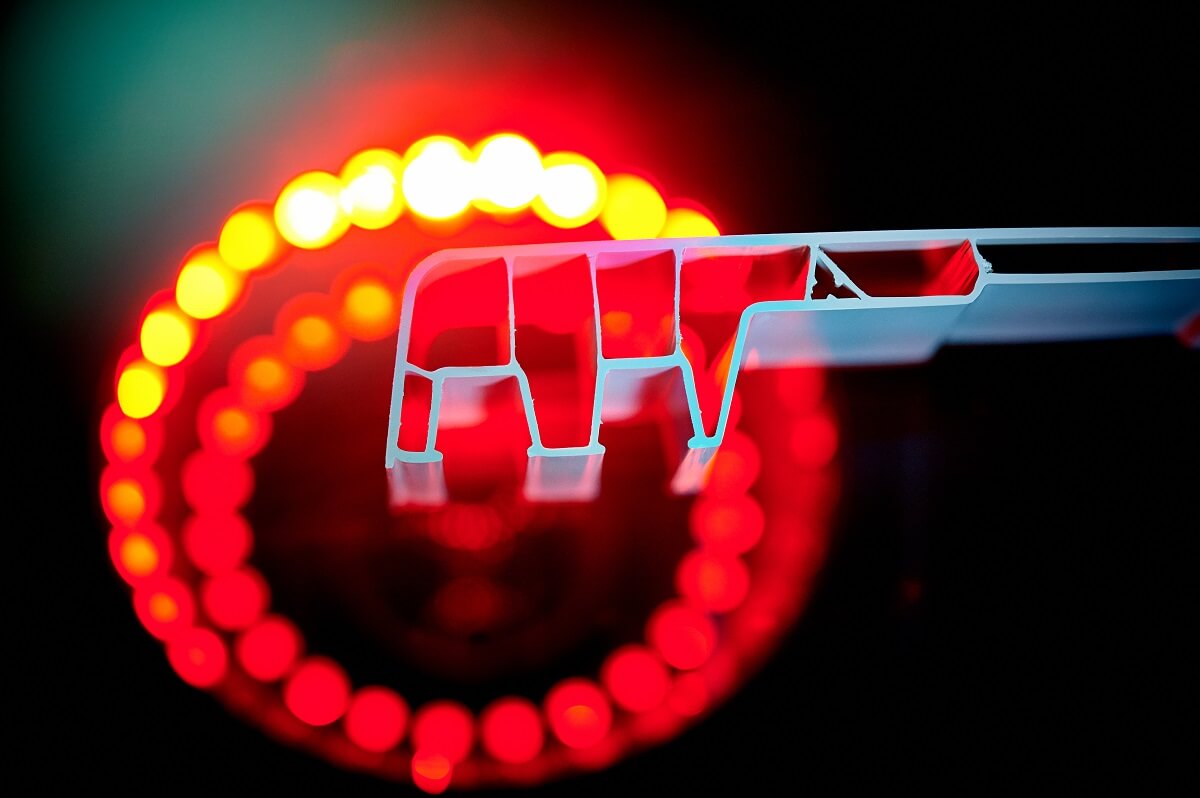

At Geplast, we use cutting-edge digital tools to meet the unique needs of our customers: scanning, modelling, CAD and 3D printing. Thanks to these technologies, we are able to produce prototypes in PVC or ABS, enabling us to validate our products with our customers. We are able to study the entire life cycle of your product before launching tooling, and we always provide a quality perspective (anticipating risks, measuring criticality in terms of product quality).