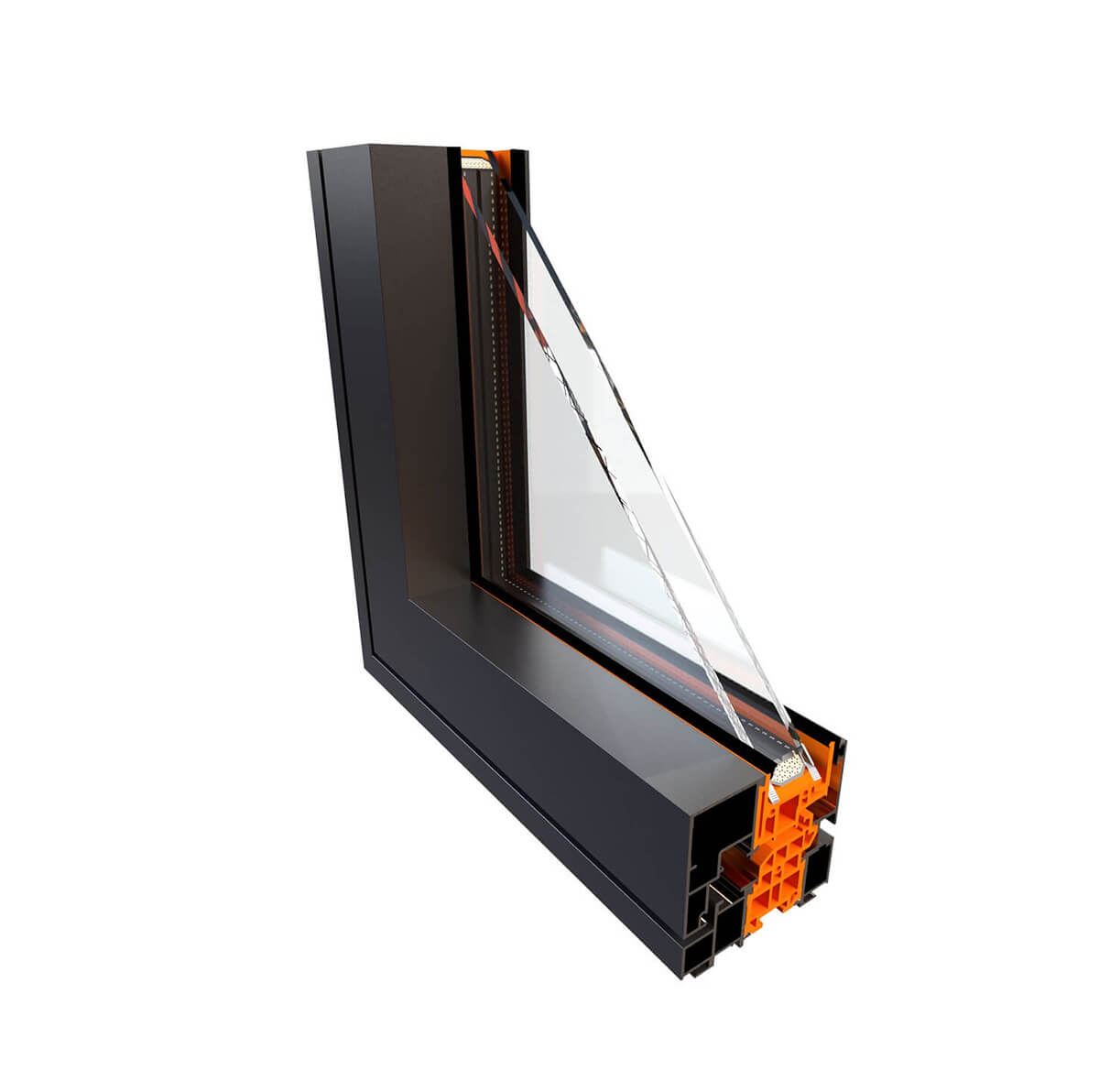

A thermal break is the barrier that limits the non-conduction of temperature between two materials. The term thermal bridge is mainly used in the building and housing sector, particularly when dealing with insulation issues.

It is an insulating element, generally made of plastic (PVC or ABS), used to create a discontinuity between two parts of metal profiles in order to improve their performance.

Thermal breaks are mandatory to obtain acceptable thermal insulation coefficients in aluminium windows or sliding doors. Thanks to these breakers, a sliding window is now 6 times more insulating than the same sliding window installed 30 years ago!

PVC and ABS are among the most insulating polymers, with a Lambda (thermal coefficient) of 0.17.

Not all thermal breaks are created equal !

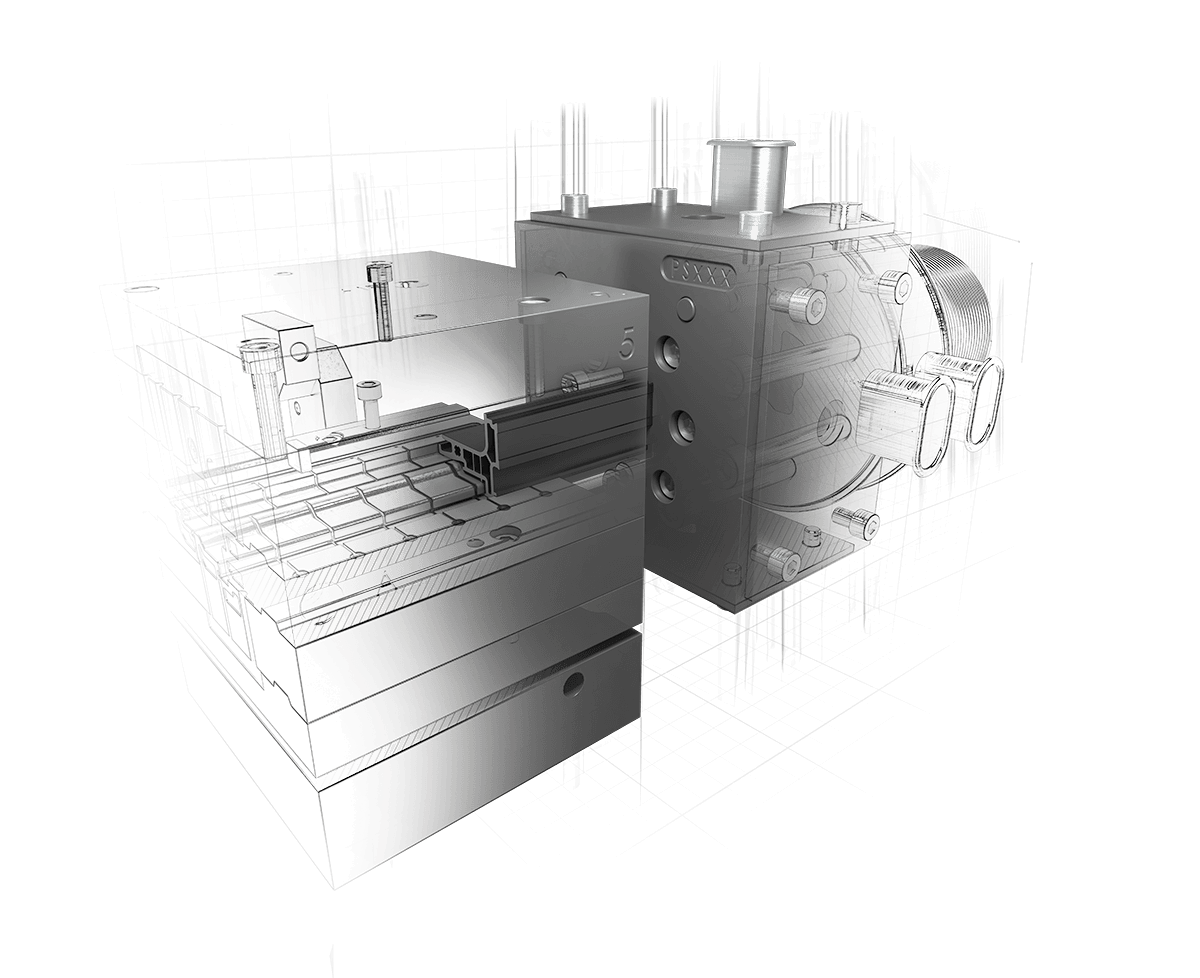

At Geplast, we take particular care to ensure that our products provide added value for our customers, which is why we take into account all current regulations. Some of our products have NF 132 certification and are manufactured in PVC or ABS. Thanks to our technical expertise and our R&D and quality units, since January 2018 we have been developing customer-specific thermal breaks in ABS that comply with the Cradle to Cradle label (industrial production that incorporates ecological requirements at every level, the principle of which is zero pollution and 100% reuse).

The benefits

Excellent thermal insulation

Good mechanical resistance

Colour properties preserved and guaranteed against ultraviolet rays

Compatible with co-extrusion to add additional soft seal functions to profiles

100% recyclable

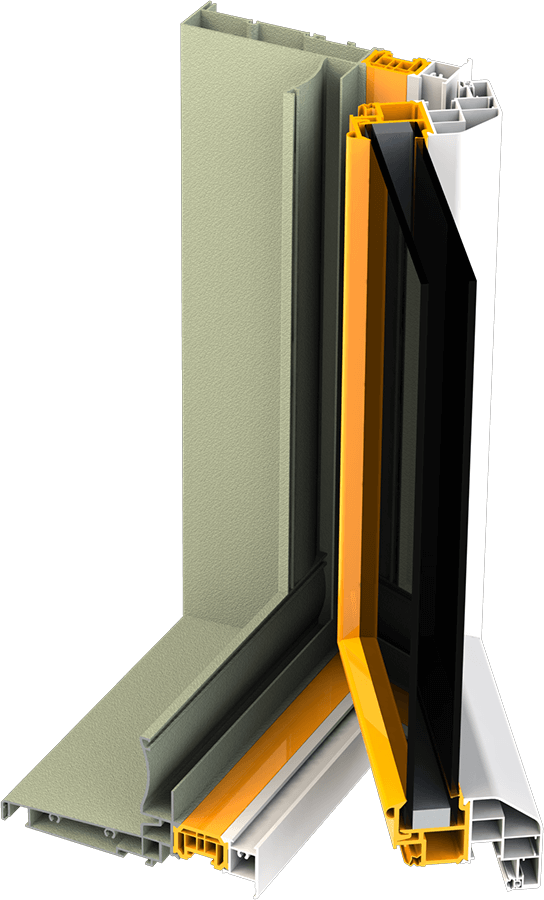

SUNY® thermal break

Geplast is launching its registered trademark SUNY®, for the creation of insulating strips for your aluminium thermal break systems made from an ABS-type polymer. Thanks to this new, technically-approved material, we can offer you unique expertise that guarantees efficiency and innovation for the production of tailor-made insulation strips for your aluminium joinery, and which complies perfectly with the Cradle to Cradle label (an industrial production label that incorporates high ecological standards at every level, based on the principle of zero pollution and 100% reuse).

With this new Geplast Engineering-certified material, we want to offer all our customers another choice, especially those who want to achieve high performance in terms of thermal efficiency, by assembling the profiles after treatment, lacquering and anodising. In this way, the SUNY® thermal break increases the thermal performance of your aluminium joinery and helps to reduce energy consumption and the heating and air-conditioning costs of your buildings.

Manufactured in France in our state-of-the-art factory, in a technical centre dedicated to the extrusion of thermal breaks, the SUNY® thermal break also benefits from excellent mechanical properties, guaranteeing regular dimensional control and a low expansion coefficient.

The advantages of SUNY® thermal break in ABS

- Excellent thermal insulation properties: lambda 0.16

- 10 times less post-shrinkage, with a Vicat point of 115 degrees, ensuring that your aluminium crimped profiles hold up better in extreme weather conditions.

- Reduced density to lighten the weight of your joinery

- Profiles can be co-extruded or post-extruded to add flexible ABS gaskets

- High extrusion precision

- 100% recyclable

Thanks to this innovation, Geplast Engineering is able to develop your specific, tailor-made strips to meet your every need and your most stringent requirements.